Robotics & Control

My team is developing new robotic platforms to tackle challenges in manufacturing, infrastructure and healthcare. We are also designing new nonlinear control techniques for existing and new systems to balance robustness with optimality.

Sensing technologies

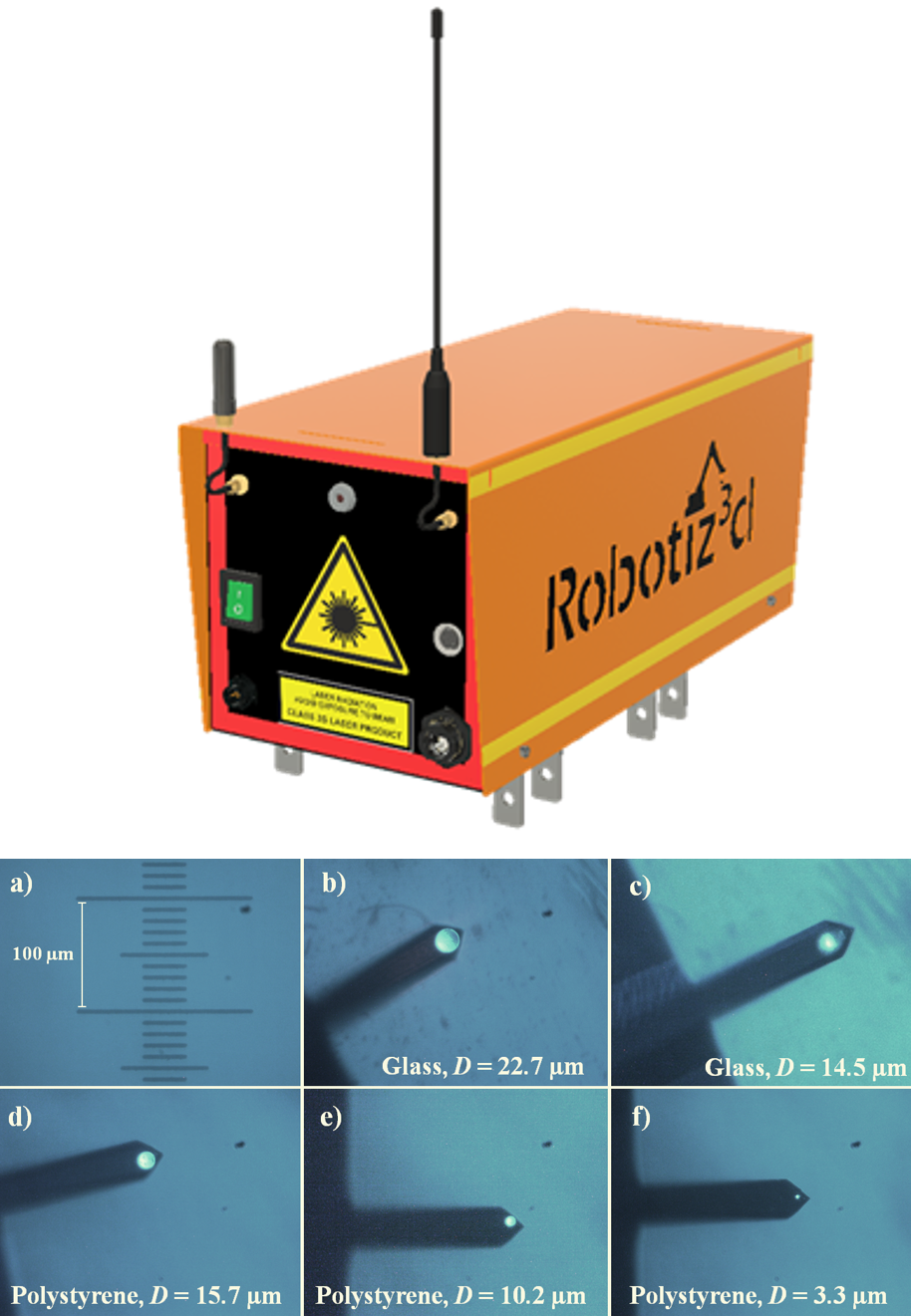

My team is developing new sensors (from nano- to macro-scale) to better monitor and control a wide range of processes, from cell evolution to road condition monitoring. We cover the full stack, from hardware design to data analytics (including ML/AI).

Advanced Manufacturing

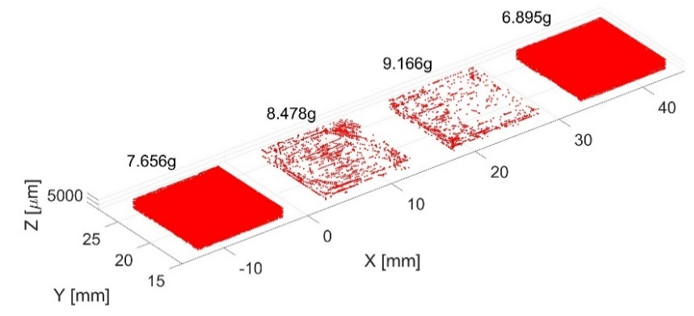

My team is interested in both designing new manufacturing approaches/equipment and in improving existing ones by using advanced sensing and control. Applications include additive manufacturing (FDM,L-PBF), lab automation and more.

Biomechanics &

Healthcare devices

Robotics & ControlMy team works on a wide range of robotics and control projects and is generally interested in how automation can be used to help humans in tasks that are either too dangerous, too time-consuming or require operators with high technical expertise. Examples of past and current projects include:

On a more fundamental level, we are interested in how optimality (e.g. minimum time or energy consumption) can be balanced against robustness to noise or model uncertainty in presence of nonlinear dynamical models. |

|

|

Sensing technologiesAvailability of high-quality data is crucial to allow us to monitor and control devices and physical processes. My team can develop bespoke sensors for a wide range of applications, and improve the performance of existing sensing platforms by controlling them and exploiting their natural dynamical behaviour. Examples of past and current projects include:

We are also interested in how control techniques can take full advantage of data-rich scenarios made available with modern sensing technology, including use of AI/ML within control strategies. |

Advanced ManufacturingManufacturing is ubiquitous in everyone's life, as all the products we use needs to be manufactured in the first place. My team is working on how to advance manufacturing processes to make them more reliable, sustainable and tailored to individual needs of end-users. Examples of past and current projects include:

|

|

> > |

Biomechanics & Healthcare devicesBiological systems excel in making mechanics, nonlinear dynamics and control work seamlessly in presence of often inaccurate sensors and actuators (compared to their engineering counterparts). My team is using mathematical modelling, data analysis and control techniques to better understand how humans and animal can achieve this, so that we can develop better sensors, assistive technology, rehabilitation devices etc. Examples of past and current projects include:

|